Growing More with Less: The Smart Way Forward

Agriculture is one of the cornerstones of a nation’s economy. With rapid population growth and environmental degradation, conventional farming is struggling to keep pace. Hydroponics—growing plants without soil—presents a sustainable alternative. Our project at EIE Engineering introduces an IoT-integrated, hydroponic system. This system has been rigorously tested in real-time to ensure optimized control of essential parameters like temperature, pH, water level, and light intensity.

About the Research Project

This project proposes a smart hydroponics model that is fully automated, and remotely monitored via IoT technology. Real-time testing has been conducted on a vertical farming structure growing lettuce and pepper plants.

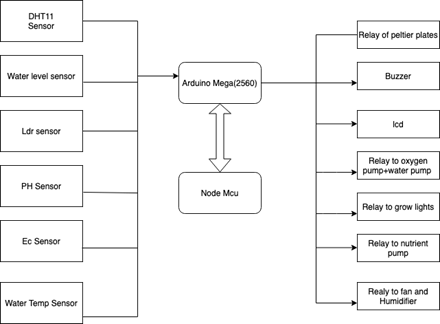

Key Components and Architecture

Hardware:

- Sensors: DHT11 (Temperature), pH Meter, LDR (Light), Water Level Sensor

- Microcontroller: ATmega2560 programmed via Arduino IDE

- Actuators: Water Pump, Peltier Module, LED Grow Lights, Buzzer, LCD Display

- Communication: NodeMCU for Wi-Fi-based data transmission to ThingSpeak

Software:

- ThingSpeak Cloud: Logs data from sensors, allows remote monitoring and control

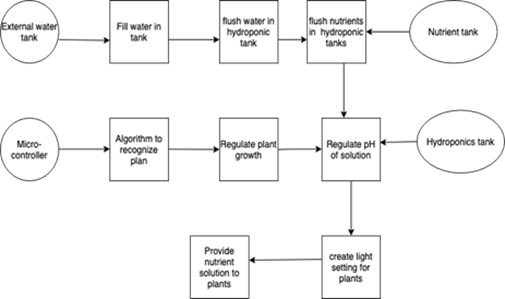

Automation System Overview

The system continuously monitors:

- pH (Ideal: 5.5–6.5)

- Electrical Conductivity (EC) (Ideal: 2.5 mS/cm)

- Temperature (Ideal: 22–28°C)

- Water Level in the nutrient tank

- Light Intensity using LDR

Actions triggered include:

- Pumping water from the reservoir

- Activating Peltier for temperature control

- Switching grow LEDs (blue 380–480nm, red 630–730nm)

- Buzzer alerts for out-of-range pH levels

Real-Time Testing and Results

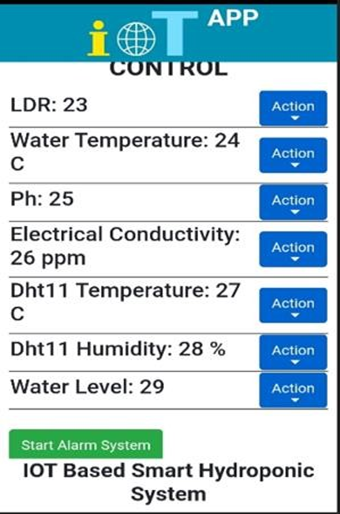

After placing lettuce and pepper saplings into the grow bed, sensor data was recorded and analyzed using graphs on Thing Speak. The microcontroller acted automatically to regulate environmental conditions. The system allowed remote access through an IoT control app.

Figures from the Study:

- Figure 1 – Block Diagram of Automation System

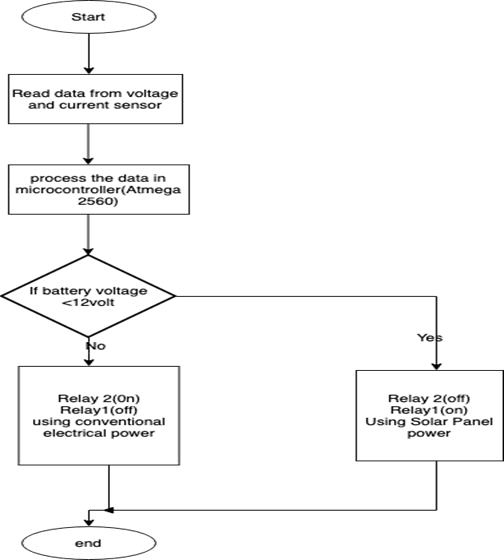

- Figure 2 – Flow Chart of Smart Solar Plant Unit System

- Figure 3 – Data Flow Diagram

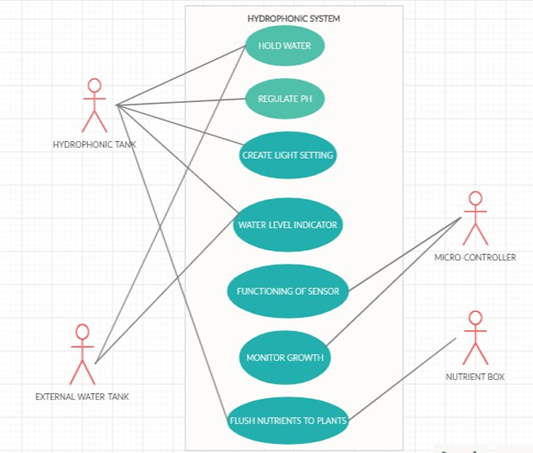

- Figure 4 – Use Case Diagram

- Figure 5 – Ideal Growing Conditions Graph

- Figure 6 – IoT Control App Interface

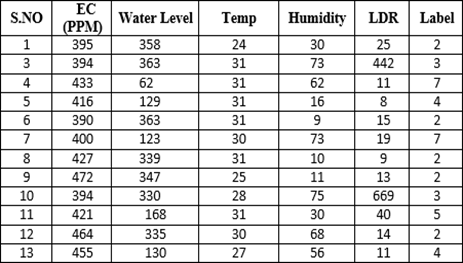

- Figure 7 – Data Collection

General Structure

The prototype was a vertical hydroponic tower designed to grow up to 20 plants. It’s portable, stable, and suitable for small-scale commercial or research setups.

Experimental Validation

Tables from the research detailed:

- Sensor Data: pH, EC, LDR, Water Level, Temperature

- Control Actions: Automated responses such as turning on/off pumps, LEDs, Peltier, and buzzers

Advantages of the System

- Real-time monitoring and action

- Reduced manual labor

- Renewable energy utilization

- Improved crop yield consistency

Future Enhancements

- Incorporating deep neural networks for plant-specific conditions

- Expanding to multi-tank systems

- Applying machine learning for predictive nutrient management

Conclusion

The EIE Engineering Team has successfully developed and tested an IoT-based hydroponic system. The system’s ability to monitor, log, and respond to plant needs in real-time makes it an excellent candidate for sustainable agriculture.

Let’s grow smarter—together.

Project Team: EIE

For research collaboration or deployment inquiries, please contact us through EIE Engineering’s official website.